Manufacturing orrganisations face increasing pressure to optimise operations, reduce costs and uphold the highest quality standards. ERP for manufacturing has become indispensable for businesses seeking to centralise processes, achieve comprehensive visibility and foster continual improvement. This whitepaper provides an in-depth examination of manufacturing ERP and manufacturing resource planning, guiding industry leaders through solution selection, implementation and maximising return on investment.

1. Introduction to Manufacturing ERP

Manufacturing ERP software integrates critical functions—such as production planning, inventory control, procurement, finance and quality management—into a single, unified system. By consolidating data in real time, manufacturers can eliminate departmental silos, enhance collaboration and make informed decisions swiftly. Key concepts include:

- Definition of manufacturing ERP: A comprehensive enterprise system tailored to the unique requirements of production-based businesses.

- Evolution: From early MRP software focused solely on materials planning to today’s full-suite, modular ERP MRP systems.

- Significance: How a modern manufacturing resource planning system underpinning ERP drives efficiency and innovation.

2. Key Drivers for Adopting ERP for Manufacturing

- Operational Efficiency: Automated workflows reduce manual intervention, minimise errors and accelerate throughput.

- Cost Control: Real-time insight into resource utilisation, procurement costs and overheads empowers organisations to contain expenditure.

- Quality Assurance: Embedded quality modules and audit trails ensure compliance with industry regulations and standards.

- Scalability: Flexible manufacturing ERP solutions expand seamlessly with evolving production volumes and product lines.

- Strategic Advantage: Data-driven insights derived from ERP for manufacturing industry systems support proactive decision-making and competitive differentiation.

3. Core Features of Manufacturing ERP

Selecting suitable manufacturing ERP software requires careful consideration of essential modules:

3.1 Production Planning & Scheduling

- Master Production Scheduling (MPS): Balancing demand forecasts against capacity constraints.

- Capacity Requirements Planning (CRP): Identifying bottlenecks and prioritising critical operations.

- Finite vs Infinite Scheduling: Ensuring realistic production plans under resource limitations.

3.2 Inventory & Warehouse Management

- Real-Time Inventory Visibility: Tracking stock levels, locations and movements.

- Batch and Serial Number Control: Ensuring traceability throughout the supply chain.

- Forecasting and Replenishment: Leveraging demand analytics to maintain optimal safety stock.

3.3 Supply Chain & Procurement

- Supplier Relationship Management (SRM): Evaluating performance, managing contracts and ensuring reliable supply.

- Automated Purchase Orders: Streamlining procurement processes and reducing lead times.

- Integration with MRP: Aligning procurement workflows with production requirements.

3.4 Quality Management

- Non-Conformance Reporting: Capturing defects and implementing corrective & preventive actions (CAPA).

- Compliance Tracking: Maintaining audit-ready records for ISO, FDA and other regulatory bodies.

- Quality Metrics and Dashboards: Monitoring key performance indicators to drive continuous improvement.

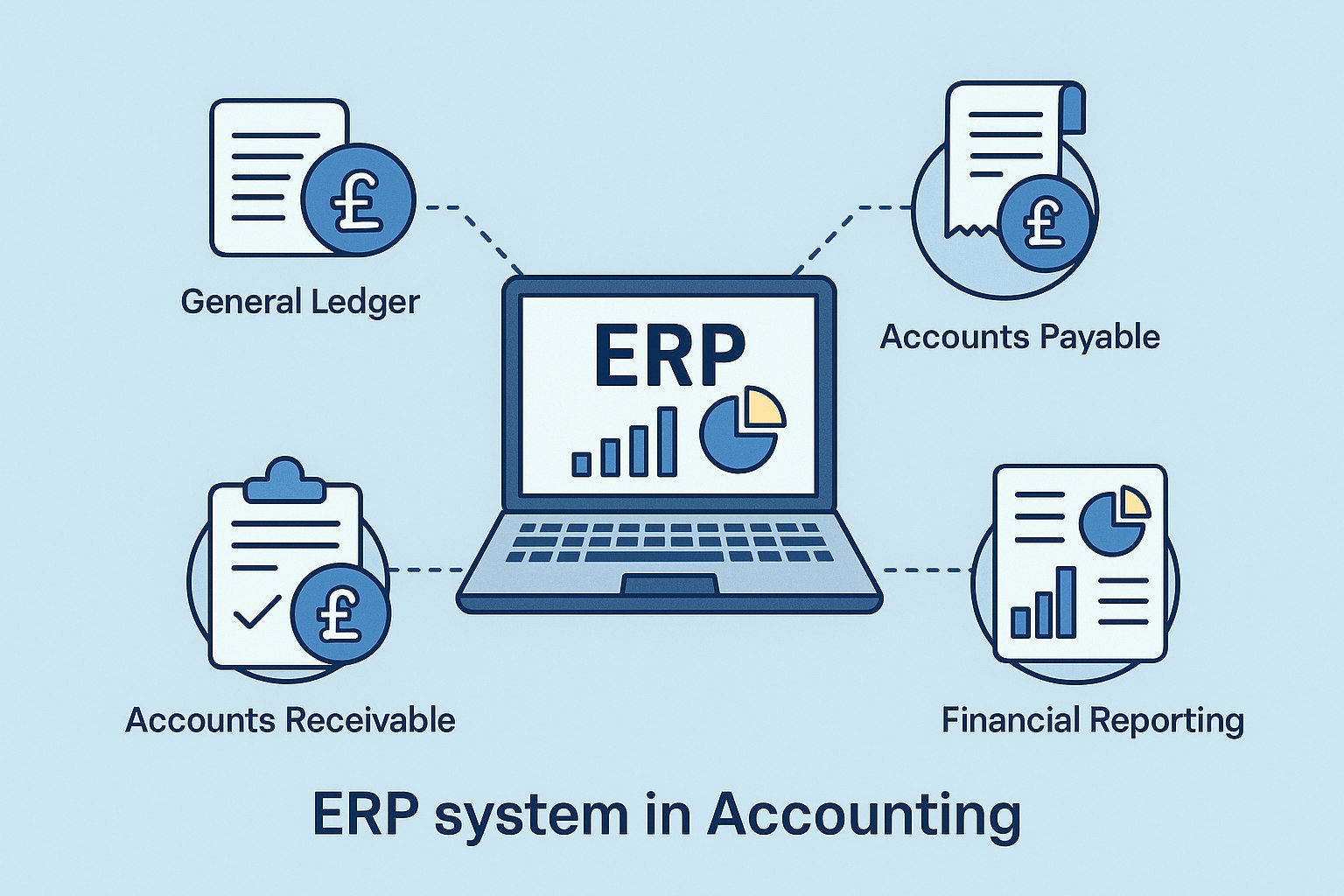

3.5 Finance & Costing

- Standard, Actual and Activity-Based Costing: Accurately allocating overheads and production expenses.

- Financial Consolidation: Unifying multi-entity reporting for consolidated financial statements.

- Budgeting and Forecasting: Supporting strategic planning with scenario modelling.

3.6 Analytics & Reporting

- Executive Dashboards: Providing at-a-glance performance metrics for senior management.

- Ad-hoc Reporting: Empowering users to generate custom reports without IT assistance.

- Predictive Analytics: Utilising machine learning algorithms for demand planning and predictive maintenance.

4. Manufacturing Resource Planning versus ERP

Although often used interchangeably, manufacturing resource planning (MRP II) and full-fledged ERP for manufacturing differ substantially:

- Scope: MRP II focuses on production scheduling and inventory control. ERP for manufacturing extends to finance, human resources, sales and beyond.

- Data Integration: MRP II integrates shop-floor modules. ERP for manufacturing provides a cohesive data architecture across the entire enterprise.

- Scalability: MRP II is generally confined to a single manufacturing facility. ERP for manufacturing scales to multiple sites, countries and business units.

- Reporting Capabilities: MRP II delivers standard operational reports. ERP for manufacturing offers advanced analytics, real-time dashboards and predictive insights.

5. Selecting the Right Manufacturing ERP Solution

A thorough, methodical approach ensures selection of the most appropriate enterprise resource planning for manufacturing industry platform:

- Process Mapping and Requirements Gathering: Document existing processes, pain points and future objectives.

- Vendor Shortlisting: Evaluate potential suppliers of ERP solutions for manufacturing industries on functionality, deployment models (on-premise, cloud, hybrid) and total cost of ownership (TCO).

- Proof of Concept (PoC): Conduct live demonstrations and limited-scope implementations to validate critical features.

- Scalability and Customisation: Confirm that manufacturing enterprise resource planning software supports bespoke workflows without excessive custom development.

- Partner Ecosystem: Engage implementation partners with proven expertise in ERP manufacturing solutions, offering training, support and change management services.

- Return on Investment (ROI) Analysis: Quantify benefits in terms of operational savings, enhanced productivity and improved customer satisfaction.

6. Implementation Best Practices

Best practices for a successful ERP software for manufacturing industry rollout include:

- Executive Leadership and Governance: Secure sponsorship from the board and establish a steering committee.

- Standardisation of Processes: Harmonise workflows to industry best practices before configuration.

- Master Data Management: Implement rigorous data cleansing and governance to ensure accuracy.

- Phased Deployment: Begin with core modules such as planning and inventory, then expand to finance and quality.

- Comprehensive Training: Develop role-based training programmes and user manuals.

- Change Management: Communicate regularly with stakeholders to manage expectations and adoption.

- Continuous Review: Post-implementation, monitor KPIs and refine processes for ongoing optimisation.

7. Measuring ROI and Business Impact

Organisations typically see payback within 12–18 months, driven by:

- Cost Savings: Lowered inventory, reduced overtime and minimised scrap.

- Productivity Gains: Higher throughput, balanced workloads and fewer bottlenecks.

- Customer Satisfaction: Improved delivery performance and responsiveness.

- Strategic Agility: Ability to model scenarios and respond rapidly to market changes.

8. Emerging Trends and Future Directions

As manufacturing embraces digital transformation, ERP will evolve in several key areas:

- Cloud-native ERP for manufacturing: Greater adoption of SaaS platforms for rapid scaling and reduced infrastructure overhead.

- Internet of Things (IoT) and Industry 4.0: Direct integration of machine telemetry into manufacturing ERP for real-time monitoring and predictive maintenance.

- Artificial Intelligence (AI) and Machine Learning: Advanced forecasting, anomaly detection and automated decision support.

- Mobile and Collaborative Technologies: Enhanced user experience via mobile apps, chatbots and integrated communication tools.

- Sustainability Modelling: Incorporating environmental metrics and carbon footprint tracking within manufacturing resource planning software.

ERP for manufacturing is not merely a luxury—it is a strategic necessity. By investing in a robust manufacturing ERP solution, adhering to best practices and embracing new technologies, manufacturers can streamline operations, accelerate growth and maintain a decisive competitive advantage.

Microsoft Dynamics 365 Business Central as an ERP Option

As a leading, cloud-based ERP platform, Microsoft Dynamics 365 Business Central offers robust functionality tailored to the manufacturing sector. Business Central integrates seamlessly with Microsoft 365, Power BI and the broader Power Platform, providing:

- End-to-end functionality: Core modules for production planning, inventory management, procurement, finance and quality control within a unified solution.

- Rapid deployment: Pre-configured manufacturing extensions and industry best-practice templates accelerate time to value.

- Scalable architecture: Cloud-native, multi-tenant environment that grows with your organisation.

- Seamless integration: Built-in connectivity with Office 365, Azure IoT and third-party applications for enhanced data insights.

Our Implementation Approach

Our specialist team follows a proven six-phase methodology to ensure a successful Business Central deployment:

- Discovery & Planning: Conduct workshops to define requirements, processes and success criteria.

- Solution Design: Configure Business Central modules and manufacturing extensions to align with your workflows.

- Data Migration: Map, cleanse and migrate master data—products, bills of materials, inventory and transactions—securely and accurately.

- Testing & Validation: Execute functional, integration and user-acceptance testing to guarantee system readiness.

- Training & Change Management: Deliver role-based training, user guides and change management support to drive adoption.

- Go-Live & Support: Provide hypercare support post-implementation and ongoing managed services for continuous optimisation.

Whether you operate small-batch production or enterprise-scale manufacturing, Dynamics 365 Business Central can be tailored to meet your specific requirements. Our experts will guide you through every stage of your ERP journey with personalised consulting and hands-on support.

For further guidance on selecting and implementing ERP in your manufacturing operations, please contact our specialist team.

Related posts

Visit blog

Microsoft SharePoint: What It Is, Why It Matters, and How to Maximise It

Explore SharePoint: intranet examples, 365 vs on-premise, Confluence vs SharePoint, plus expert consultancy advice in this in-depth SharePoint guide

Business Central Accounting Software Explained: A Complete ERP Accounting Guide for Modern Finance Teams

This guide explores the key features, benefits, and reasons why Business Central accounting software stands out as the preferred ERP choice for small to medium-sized enterprises (SMEs) and growing finance teams.

Choosing the Right Power BI Consultancy in London: Expert Guide

This guide will help you understand what to look for when choosing a Power BI consultancy, the benefits of working with London Power BI Experts, and why partnering with the right London Business Intelligence Consultants is important